We know that millions of fabrics in the market claim to be flame resistant (FR), but some sellers use cheap or fake materials to earn huge profits and risk your business and brand.

If you are looking to find a way to evaluate flame-resistant performance, distinguish between inferior and qualified flame-resistant fabrics, and get saved from a scam, then you have come to the right place.

There are two important ways to measure and test the flammability of fabrics, which are:

- Limited Oxygen Index ( LOI )

- Vertical Burning Test.

We will discuss how to perform these tests, and what test results you should expect. Lastly, we will tell you some commonly used flame-resistant fabrics.

Now let’s dive into it.

What is LOI?

LOI, also known as the Limited Oxygen Index, is;

“The minimum concentration of oxygen ( in percentage ) required by an object to burn and if the value oxygen value is any lower, the object will not combust.”

The LOI value of a material can be determined by specific test methods, commonly known as ISO 4589 and ASTM D2863.

How to perform the LOI Test?

- The fabric is placed in an enclosed container vertically.

- Then, a mixture of oxygen & nitrogen is passed from the bottom to support combustion.

- The top end of the material is ignited & it starts burning with a candle-like flame.

- Now, the concentration of the oxygen mixture is decreased to a point until all the flames extinguish. And this value is the Limited oxygen Index of the object.

Various Fabrics LOI Values

Of course, different materials have different flammability, so their LOI value will also be different.

The higher the LOI value of a material, the more oxygen fuel it needs to burn, and the harder it will catch fire.

The textiles with LOI values greater than environment oxygen levels ( 21% ) are called flame-resistant fabrics.

The LOI values of Different materials are given below;

Fibers

LOI Value

Environment Oxygen Content

Flame Retardant or Not

Cotton

18%

21%

×

Polyester

22%

21%

×

Nylon

23%

21%

×

Wool

24%

21%

√

Modacrylic

26-34%

21%

√√√

Aramid (Nomex, Kevlar)

25-28%

21%

√√√

It should be noted that the above cotton is not fire resistant at all. At the same time, Polyester, Nylon, & Wool can somewhat resist combustion.

All these materials are made excellent Fire-retardent materials by either treating them with FR chemicals or blending them with FR materials like Modaacrylic, Aramid, etc.

For example, a premium FR knitted fabric by blending 25 ~ 30% wool with fire-retardent viscose or modacrylic. The combination incorporates the comfort and moisture-wicking features, meanwhile does not cause the modacrylic to lose its natural flame resistance properties.

What is the Vertical Burning Test?

Vertical Burning Test is a test method known as EN ISO 15025:2016, which is included in European PPE (personal protective equipment) standard EN ISO 11612; it is a test specially designed for heat & flame protective clothing & textiles.

This test measures the 3-basic things;

✓ How fast does Flame Spread on a vertically suspended fabric, from one end to another?

✓ How many seconds does it take to self-Extinguish?

✓ What kind of damage does it sustain during burning, like hole formation.?

You should note that this test can be performed on single skin, multiple layers, & treated fabrics. But it is not fit for excessive melting & quick-shrinking ones.

Vertical Burning Test Procedure

According to the EN International Standards of Organizations ( ISO ), you can proceed with the test in 3 Steps;

Step 1 Fix the Fabric Specimen

- First of all, hang the fabric vertically on a stand.

- Make sure room temperature and humidity is optimum.

- Make sure to stay away from flammable items

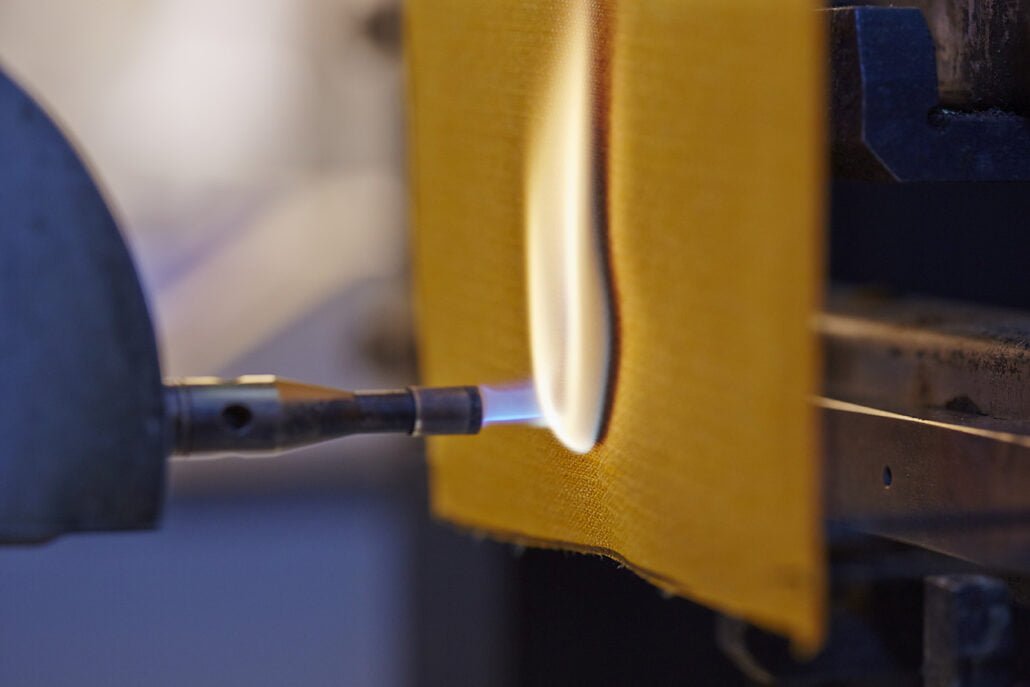

Step 2 Burn the Specimen

Now, it is time to throw flames at the specimen with a burner, just like in a real fire. You can burn the samples in 2-ways;

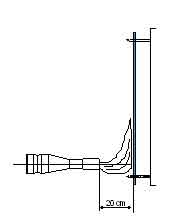

- Procedure A: Place the burner horizontally to the surface of the fabric

- Place the burner in front of the Fabric ( Horizontally to Fabric), just a little above the Fabric’s lower end or stand pins.

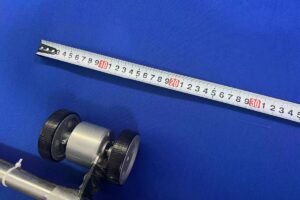

- Make sure the burner is just 20 mm away from the Fabric.

- Set the Flame horizontal reach ( throw ) to no more or less than 25 mm.

“Using this method, test at least Six Specimens for Best Results.”

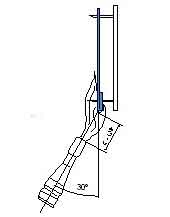

- Procedure B: Place the burner under the edge of the fabric

- Place the burner under the Fabric’s lower end at an angle of 30°.

- Make sure the distance between the burner edge & lower fabric end is no more than 20 mm ( ± 2 mm ).

- Adjust the flame height or throw to 40 mm.

“Using this method, test at least Six Specimens for Best Results.”

Step 3 Take Readings

Set the Fabric on Flame for 10 seconds in both above methods, and take the following readings;

| Check Items | Results |

|---|---|

| Flame reaches any other fabric edge or not? | |

| After-flame time, ≤2 seconds | |

| Ager-glow time, ≤2 seconds | |

| Length of char formation(Brittle area at the edge) | |

| Fabric chipped off and feel off as debris? | |

| Did hole form or not? ≤5mm |

Note:

- After-flame time is the amount of time a Fabric continues to burn after the source of fire is removed.

- After-glow time is the time a fabric continues to glow after the end of the flames. Afterglow burning can convert to afterflame burning under certain conditions.

- Less than 1.0 Seconds is considered Zero.

- What Fabrics are Flame-Resistant?

“Strictly speaking, Flame Resistant fabrics are those which naturally have resistance to burning and self-extinguish when the source of fire is removed. However, artificially enhanced combustible fabrics also fall under this category.”

Nowadays, four types of materials are commonly used to make protective clothing:

- Modacrylic

- Nomex IIIA

- Lenzing FR

- Treated FR-Cotton

Materials

Natural FR

Composition

LOI Value

Modacrylic

√

100% Modacrylic; Modacrylic & Cotton Blend

26-34%

Nomex® IIIA

√

93% M-aramid, 5% P-aramid, 2% Carbon

28%

Lenzing® FR

√

Wood-based cellulosic fibers

>28%

Treated FR Cotton

Treated with chemicals to make it permanent FR at 50 cycles of washing.

100% Cotton; 88/12 Cotton & Nylon Blend; CVC:60% Cotton, 40% Polyester Blend

>28%

FAQs

Is 100% Polyester Flame Resistant?

Not quite accurate, you can say 100% Polyester is somewhat Flame-Resistant because;

Any material having an LOI value greater than environment oxygen concentration ( 21% ) is considered flame-retardent, and Polyester has a 22% LOI value.

Theoretically, Polyester will start melting at 220° C, and then it catches fire around 440° C, making it harder to burn than cotton & linen.

Although it is true, the LOI value of Polyester is 22%, higher than 21% Atmospheric Oxygen Concentration but only 1% higher, which is not that much. If heated enough, it will eventually catch fire & melt.

“In summary, you can only say that 100% Polyester is difficult to burn, but it’s not Flame resistant, as it can’t be self-extinguished after removing the fire source.”

Is Wool Flame Resistant?

Yes, wool is a naturally good flame-resistant material which an LOI value of 24 ~ 27% ( Materials with a 25% LOI value or greater are fire resistant ).

Wool is considered one of the greatest flame-resistant materials with the following characteristics;

- Self-extinguish quickly.

- Low heat release during burning.

- Form soft dissipating ash ( does not melt or drip like synthetic fabrics ).

- Form a carbonized barrier that prevents further flame spread.

- Does not burn easily ( High ignition temperature 570° ~ 600° C ).

- High Nitrogen ( 14% ) &moisture content.

“Wool is way better fire- retardant than cotton, linen, polyester, & nylon.”

Conclusion

At last, by using the vertical burning test, you can easily find out at your place what grade of FR-fabric in which you purchased or will buy.

You can replace the burner with a match, lighter, or alcohol lamp to simulate the laboratory test method.

We will show you how to do it simply at home or office step by step in another article.

Moreover, if you are looking to find FR fabric for protective clothing, base layers making, vests making, gloves, or other consumer products, then you have come to the right place.

With over 15+ years of experience in the Fire-Resistant industry, we WOKI® can provide FR fabric in various blends & colors, all at cost-effective prices. One of the main benefits of buying from us is that all products comply with PPE standards and are 100% tested & certified. You can expect a third-party inspection before shipping.

3 thoughts on “How Can I tell if the Fabric I purchased is Flame Resistant?”

You explained all aspects in a very effective way. We are India based company manufacturing IFR fabrics.currently We are looking to broaden our range of fr fabrics and looking for a good consultant who can provide online services.is that workable?

Hi Nitin,

Glad to know it’s helpful to you. Yes, we offer online services to support you on FR fabrics. Our expert will contact you at the soonest.

Regards,

Kevin

I would like to create different patterns for workers to enhance their appearance on the job site lot of personal do after work activities.

So how do I go about making my own designs?