FR Fabric Manufacturing Process

An overview of technical textiles manufacturing. You will benefit from our quality flame retardant fabrics.

Yarn Preparation

We carefully select and source the yarns with designed fiber blends. At our facility, we convert the different sizes of tube yarns into high-volume cones. Then assemble it onto standard-sized warp beams. Get it ready for knitting processing. This step is crucial for continuous manufacturing.

Knitting

Next, on our advanced textile machines, high-speed crochet hooks drive the yarn through complex motions to form different loop structures. The raw fabric comes out at this stage, it’s called “greige fabric“. With our techniques, we can produce flame retardant knitted fabric in various styles, including:

- Single Jersey

- Interlock

- Pique

- Mesh

- Single Fleece

- Ribs

- Eyelet (Bird eye mesh)

- Terry & Towel

- Polar Fleece

Dyeing

Bleaching the greige fabric, to remove the pigment of the fiber itself and improve the whiteness, allows fabrics to be colored more easily. The finished product will get bright color shades. Now the fabric is ready for dyeing. It’s called “RFD fabric”.

Finishing

Our flame resistant fabrics are modacrylic blended with cotton or other multi-component fibers. We select cationic dyestuffs combined with reactive dyestuffs so that the different fibers can fully absorb the dyes under high temperature and high pressure in the overflowing tank. In this way, the finished fabric will have good color fastness.

The dyed fabric will be processed with stretching and dimensional stabilization to acquire fixed width, gram weight, fine-looking, and customized softness to hand.

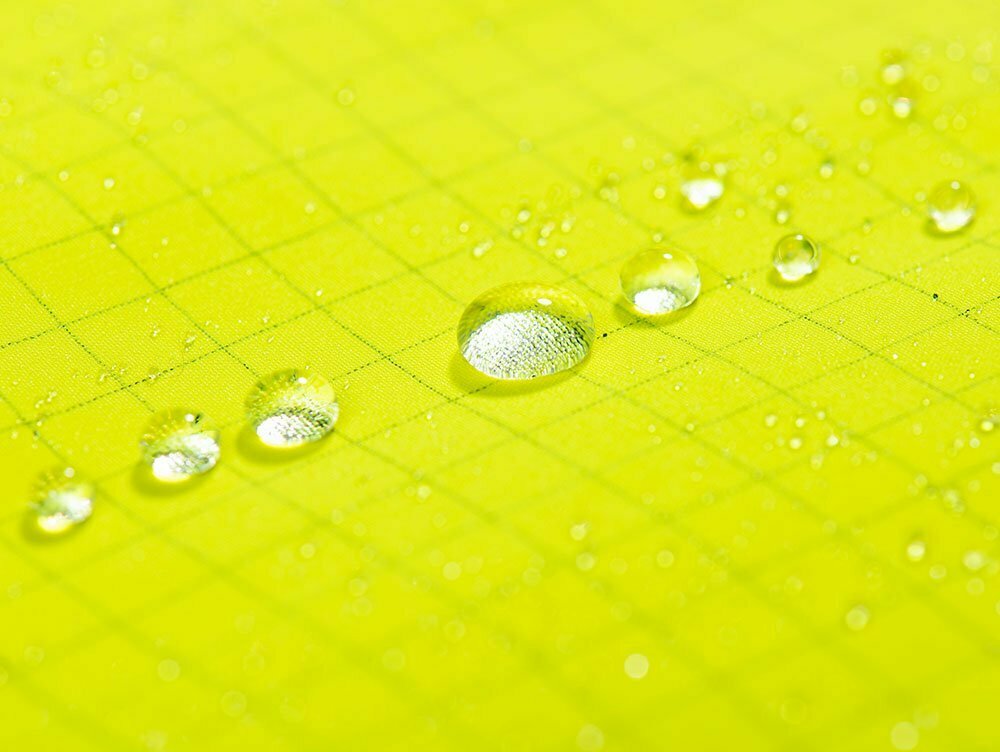

Coating & Lamination

The process of coating and laminating textiles is complex. The formulation is the key. We can customize the chemical additives for coating compounds to meet our customers’ performance needs. We balance numerous influencing factors to achieve specific requirements such as breathability, waterproof, moisture permeability, elasticity, and firmness.

- PU, PTFE Membrane

- PU, PVC Coating

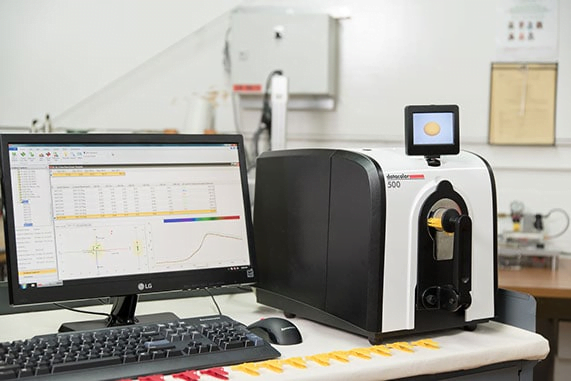

Inspection

Before fabric rolls can be shipped to customers, they must undergo a careful visual inspection to ensure no defects are found. The unacceptable defects included big holes, out-of-range width, and fabric weight.

Packing

Once all rolls are checked, they are loaded onto a conveyor belt and fed into the packing machine. The packing machine wraps each roll in a water-proof and moisture-proof woven bag or transparent plastic film.

Storage

The end of the rolls is sealed and labeled with the appropriate order & shipping information. Finally, the rolls are placed on a pallet and loaded onto a lift truck. All fabrics ready to be shipped are placed on shelves in the warehouse.

Professional FR Fabrics Manufacturer from China

Quality fabrics exceed market standards. Give confidence in your protective wear.

Consult Our Expert of FR Fabrics

Our team will help you achieve your performance and quality goals.