Approximately 340 million occupational accidents occur each year. Due to low visibility, most accidents involve heavy machines and moving vehicles hitting workers.

So, it is a must to wear safety workwear of high-visibility materials by law. In Europe, EN 20471 standard sets the requirements for such clothing.

What are the classifications for different high visibility levels?

How is it different from the previous EN 471?

If you want to learn more about this standard, you have come to the right place.

What is High Visibility Clothing?

“Any Clothing that is highly luminescent or easily recognizable from the rest of the background is called High-Visibility Clothing.”

High-Visibility Clothing is also sometimes known by the names such as Hi-Viz, or Hi-Vis clothing. It is mostly used for Construction, Roadside, Railway, Factory, and all other fields of workers & visitors.

The primary purpose of Hi-Vis clothing is to distinguish wearers from the rest of the environment.

It is particularly important in environments with many moving vehicles and equipment. It helps to reduce the risk of accidents by making it easier for workers to see each other and avoid collisions.

How does High-Viz Clothing Work?

High-Viz clothing consists of three parts.

- Fluorescent Color Materials

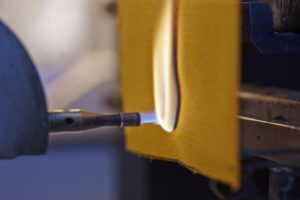

Fluorescent colors appear to “glow” when exposed to ultraviolet (UV) light. Typically, these colors are used for safety, as they are highly visible and can be easily seen in low-light conditions.

Fluorescent colors are often used in high-visibility clothing, reflectors, and other safety gear. They appear brighter and bolder than standard colors.

The Science of Fluorescence

The molecules of Flourescent colors have electrons at the Unexcited-Ground state. When photons of light fall on it, the electrons absorb them and jump to a higher stater level-Excited state. But, they fall back to an Unexcited state-Ground State after some time. And when they fall back, they release the absorbed energy in visible light.

As Flourescent colors absorb & emit both visible light & Ultraviolet light. This advantage makes them shinier than standard colors, which can only work with visible light.

There are 2-types of Flourescent colors;

- UV-Reactive; They will only glow when Ultraviolet light ( no normal light ) falls on them. And when a light source is removed, it will stop glowing.

- Glow-in-the-Darl; These absorb both visible & UV light, get charged and will keep glowing for some time after the light source is removed.

- Reflective Material Stripes

You probably already know that Reflective material simply bounces back the incident light and makes the cloth shiny.

It can work both during the day & night ( only in light ). So, it helps to give a quick signal to the observer.

Contrasting colors such as black or navy enhance the functionality of the garment.

The parts covered with contrast fabric tend to be where the dirt builds up, like the end of sleeves, elbow, knee, and ankle.

Since these colors are darker and less vulnerable to earth, they ensure the garment remains highly visible and fully functional.

Yellow Vs. Orange, Which Hi-Viz Color is Safer?

There are three hi-vis colors approved for safety garments, such;

- Red

- Yellow,

- Orange

Among these colors, Yellow and Orange are the majority ones chosen by Health & Safety personnel.

“Yellow Color attracts more Insects than Orange.”

Dramatically, while researching fluorescent colors for this post on the internet. On my laptop screen, a hi-vis yellow picture accidentally attracted a mosquito.

Both Yellow & Orange have their benefits & demerits. When purchasing protective apparel of a specific color, you must consider 3-factors below;

- Background Environment

You should select a color that differs significantly from the background of your workplace. Fluorescent colors will make you stand out from the rest of your colleagues at the workplace.

For example, if you wear a sage green jacket for hunting in the forest. It will match the green trees, plants, etc., and nobody will be able to distinguish you.

Hunte should wear an orange garment. It helps your companions or other hunters to identify you. Because no wild animals have an orange color.

The following chart shows the applications where fluorescent colors are often used.

| Natural Background | Artificial Background | |

High-Visibility Color | “Orange Hi-Viz is Best” Because Orange is artificial color, not found in nature. | “Both Yellow & Orange Hi-Viz are Best”: Yellow is a natural color, not found in artificial areas. And Orange is unique color even in artificial regions. The color orange represents danger in the subconscious. “Yellow is preferable because it is the brightest on the Chromaticity Scale.” |

| Environment Examples | RailwayHuntingRoadsides Auto Warning Triangle Water Bodies, oceans, rivers, etc. | FactoriesWarehousesPower PlantsConstruction SitesElectric Poles Working, etc. |

It is interesting to note that the fluorescent yellow color in the railway looks like a green light from a distance.

It delivers a wrong signal of “Go-Ahead.” It may cause a severe accident.

The orange color stands out in the background because the railroad usually passes through rural and suburban areas with few urban buildings.

- Who is Gonna Wear it?

“On a site, the workers, superior officers, & visitors should wear different color clothing so each of them can be easily recognizable.”

Construction sites require contractors to wear high-visibility yellow safety vests, for example. Visitors should wear orange or red to stand out.

- Common Sense

Psychological Recognition of the color should also be considered when choosing Hi-Vis clothes.

“Psychological Recognization is how a Human mind understands a Color.”

Usually, the orange color represents warning and danger. In contrast, yellow represents warmth & sunshine. So, using orange color to warn others of risks is more sensible than using yellow color.

For example, you may often see orange color at the place where road construction or maintenance is taking place. Moreover, triangle safety signs and other road items also use orange color.

People can recognize the orange color faster than the hi-vis yellow color under emergency. So it’s commonly used for emergency rescue, forest fire fighting, and railway industries.

What is EN ISO 20471 High-Visibility Standard?

In 2014, OSHA Europe released a new version of the standard EN ISO 20471:2013.

It’s the international standard for high-visibility clothing.

According to this standard, the reflective material must have a minimum coefficient of retroreflection of 0.2 cd/lux/m2. And the fluorescent color of background materials can be orange, yellow, or red.

For different risk levels, there are three classifications of hi-vis clothing.

Class 1 is the lowest level of visibility and is typically used in environments with a low risk of injury.

Class 2 has a medium level of visibility than Class 1 but is still considered highly visible. It’s often used in environments with a moderate risk of injury.

Class 3 has the highest level of visibility, and the wearers can be visible from all blind angles during day & night.

Below is a chart that shows the amount of minimum Reflective & Fluorescent material required for each clothing class;

| Class 1 | Class 2 | Class 3 | |

| Reflective Stripes | 0.10 m² | 0.13 m² | 0.20 m² |

| Fluorescent Material | 0.14 m² | 0.50 m² | 0.80 m² |

Difference between EN 20471 and EN 471 Standards?

EN ISO 20471, released in 2013, is just an upgradation of the old EN ISO 471 standard ( 2004 ) of high visibility clothing regulations. The new standard is not much different from the old one, but there are a few amendments worth reading, like;

| EN 471 ( Old ) | EN 20471 ( New ). | |

| Various Risks are defined | Less | More |

| Tensile/Bursting Strength | More | Less |

| Include Usage According to Class | Fewer Examples | More Examples |

| Clothing Must Cover Part of Body | Torso only, Sleeveless is possible ( Class 3 ) | Torso & Sleeves ( Class 3 ) In Class 2, Sleeveless is possible if wearing Full-length Striped Hi-Vis Work Trousers |

| Color Testing after Max. Wash Cycles | Not necessary in all classes | Must in all Classes |

| Tear strength ( Coated materials. ) | More | Less |

| Colorfastness Requirement for Non-Fluorescent Background material | More | Reduced |

| Colorfastness to Perspiration | Minimum 3 Class | Minimum 4 Class |

| Physiological performance ( Water Vapour & Thermal Resistance ) | Less Detail Specified | More Detailed Specified |

| Bib & Brace | It can be Class 3 ( because Sleeveless is possible ) Reflective Stripes around the legs are 50 mm. | It can only be Class 2 because, in Class 3, Sleeves are a must. Reflective Stripes around the legs are increased from 50 mm to 60 mm |

| Sleeve Strips | If half sleeves obstruct the torso reflective band, there is no need to add strips on the sleeves. | Full Hi-Viz sleeves, no need for stripes. If Sleeves ( full/half ) consist of contrasting colors and obstruct a fluorescent material of the torso, then you must add reflective stripes to the sleeves. |

Who Needs to Comply with EN 20471?

This standard is mandatory for all workers exposed to low visibility risks, such as those who work in construction, road maintenance, or airports. Employers must provide their employees with high-visible clothing.

If you are a fabric buyer, garment distributor, or importer. Anyone who wants to sell products in European countries. You must ensure that the products comply with the EN 20471 standard.

All garments that pass EN20471 will be CE certified and only then will they be allowed to be sold on the EU market.

What’s Next

If you are looking to find High-Visibility Clothing, then we, Woki®, are the one-stop solution for you. We can provide all 3 Classes of Hi-Viz clothing in any color, design, & stripe pattern you want. All our products have CE certification of EN 20471 latest standard.

Our Hi-Viz Clothing has high tensile & Tear strength with excellent Colorfastness after tens of wash cycles. With 15+ years of experience in protective clothing, we can also provide Hi-Viz materials in all levels of FR ratings.