Industrial workers are at risk of exposure to a variety of hazards. The most common is heat and flame hazards.

In order to reduce potential risks and injuries, it is vital to wear protective workwear that meets the requirements.

How do you ensure that these protective clothing provide adequate protection?

EN ISO 11612 is such a standard that sets forth requirements for protection against heat and flame.

In this blog post, I will discuss what EN ISO 11612 covers and how it can help protect workers.

What is the EN 11612 standard?

The EN 11612 standard is a European Standard that establishes the requirements for heat and flame protective clothing worn by workers exposed to heat and flames. This standard PPE regulation EU 2016/425 is also known as the PPE Directive.

Additionally, the standard also confirms if the garment meets minimum levels of shrinkage, resistance, and lifetime. Note that EN 11612 standard has optional and mandatory test items. The standard consists of a series of testing items divided into three main parts:

- Part I: Basic Flammability Test

- Part II: Physical Performance Test

- Part III: Thermal Risk Test

A garment must pass all the mandatory tests to acquire the EN 11612 standard certification. Each test item will be indicated by a letter code, followed by the number 1-3 representing the level achieved.

Know the letter codes in EN 11612 standards

If you are a fabric buyer or a safety manager, don’t just focus on the classification displayed. Also, pay attention to the data in the test results.

For instance, the garment might have achieved level-2 of the D or E code (represented by D2, E2). It means the protective garments can protect against molten metal splash. However, the amount of molten metal spatters the fabric can withstand differs. Therefore, it is wise to ask for a detailed test report in addition to the test certificate provided by the supplier.

As you can see above, not all protective clothing has equal protection levels. You should also not fall into the price trap by comparing prices and choosing the cheapest one, as that could be misleading. In flame retardant fabrics, price always relates to the quality of the material and how it performs.

Pre-treatment condition

As a safety manager or FR fabric buyer, you should also consider how many cycles the fabric can withstand washing.

For example, you would generally use treated cotton FR coveralls in drilling, offshore oil exploration, and other onsite work in the oil & gas mining industry. Because of this, they face more severe contamination. The soiled workwear requires frequent industrial washing.

Therefore, you must ensure that the coveralls meet ISO 15797 for industrial washing (above 75°C) rather than ISO 6330 for home washing (40°C).

Washing Cycles

Same as above, you must note that the 11612 standards only require the fabric to withstand a minimum of 5 washes, which is not enough for treated FR fabrics. Nowadays, most suppliers in the market can offer treated FR fabrics that can withstand 50 washes.

Mandatory Tests

EN 11612 standard has mandatory and optional test items. To get the go-ahead to sell a protective fabric or garment in the EU, it must pass all necessary test items to acquire a full EN 11612 test certificate issued by an accredited lab. Let’s start by examining the mandatory test items:

PART I: Basic flammability tests

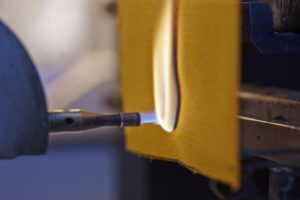

Flame Spread – ISO 15025 – code letter A

It examines the performance of the fabric material for limited flame spread when in contact with flames.

For this test, apply a flame to the fabric material for 10 seconds. To pass the test, the clothing should stay within the tolerances for the formation of holes after flame and afterglow times. Two specific procedures depending on where the flame acts on the fabric. Both test methods are required to conduct on samples as received and after washing.

- Procedure A: It tests for surface ignition where the flame is applied horizontally on textiles.

- Procedure B: It tests for edge ignition where the flame is applied vertically on textiles.

Safety managers should check the product’s main label on clothing. If it shows both A1 and A2 markings, the garment offers excellent FR properties.

Heat resistance at 180°C – ISO 17493

The test item evaluates the ability of the fabrics to resist shrinkage when exposed to 180°C hot air for more than 5 minutes. The fabric should not shrink by more than 10%.

Air flowing between the FR garment and the wearer’s body is a layer of insulation against heat energy. Safety managers should select loose-fitting FR garments as tight-fitting ones will not allow this air to protect the wearer.

“Certificate issued by Laboratory only after the fabric passed heat shrinkage test, tensile, tear strength or burst strength, and the flammability test of procedure A or B.”

PART II: Physical Performance

Dimensional change – ISO 5077

It is a test to verify the fabric’s ability to maintain its linear dimension and external boundaries after five washes and drying procedures.

Tensile, tear strength or burst strength – ISO 13934-1, ISO 13937-2, or ISO 13938-1

Tests the clothing fabric to resist pulling forces. It determines the maximum amount of force the clothing can bear before it breaks:

- Part 1 (ISO 13934-1) uses the strip method to determine the maximum force and elongation. The minimum should be 300 Newton (N) to register a pass.

- Part 2 (ISO 13937-2) measures the tensile property to gauge maximum force using the tear method. The garment should resist a minimum force of 10 N.

- ISO 13935-2 determines the maximum perpendicular force you can apply to the seams before it ruptures, using the grab method.

- ISO 13938 uses hydraulic and pneumatic methods to determine bursting distension and strength.

Optional tests

Part III: Thermal risk tests

Thermal protection tests are optional, but fire and heat hazards are often present simultaneously in the workplace. The fabrics usually pass the testing of heat transfer and heat radiation. The most common requirements are EN 11612 A1, B1, C1

Convective Heat – ISO 9151- code letter B

This test gauges the fabric’s protection against convective heat, that is, the transmission of heat when you expose it to flames.

Bring the textiles close but not in contact with the heat, then measure the temperature on the other side using a calorimeter. The goal is to determine how long the temperature on the other side rises to 24°C. The lab will then assign the garment a category score according to its performance in the test:

- B1: less than 10 seconds (basic protection)

- B2: more than 10 seconds, but less than 20 seconds

- B3: longer than 21 seconds (high protection)

Radiant heat – Code letter C – ISO 6942

It is similar to the convective test, only this time they test against infrared rays (radiant heat). Expose one end of the textiles to radiant heat and measure the unexposed end to determine how long before the temperature rises to 24°C. Use a radiant heat source with at least 20 kilowatts. Here are the classifications:

- C1: at least 7 seconds and more, but less than 20 seconds (basic protection)

- C2: 20 seconds or more, but less than 50 seconds (middle protection)

- C3: 50 seconds but less than 95 seconds (high protection)

- C4: 95 seconds or more (highest protection)

Contact heat – Code letter F – ISO 12127

It determines the fabric’s contact heat properties when in direct contact with the heat source. The test involves placing a fabric material over a cylinder heated to over 250°C and measuring the temperature on the other side. Requirements for Code F:

- F1: withstands for at least 5 seconds, but less than 10 seconds (basic protection)

- F2: 10 seconds < 15 seconds (middle protection)

- F3: 15 seconds or longer (high protection)

Molten splash heat – ISO 9185

There are two tests conducted: molten iron and molten aluminum splash. The testing procedure deals with examining the protective ability of the clothing against molten metals when you apply molten metal to the fabric. That determines the minimum mass needed to damage the layer of the material.

Code letter D represents the test for resistance against molten aluminum splash, while Code letter E is the test for resistance against molten iron splash. Requirements for parameter D:

- D1: 100 grams or more, but less than 200 grams (basic protection)

- D2: 200 grams or more, but less than 350 grams (medium protection)

- D3: 350 grams and more (high protection)

For code E, the parameters are thus:

- E1: 60 grams or more, but less than 120 grams (basic protection)

- E2: 120 grams < 200 grams (middle protection)

- E3: 200 grams or more (high protection)

The practice of the ISO 11612 standard

The ISO 11612 provides set standards, but it may not always match the safety needs of your workers. Before you settle on an FR garment, you should keep the following in mind:

- Remind your workers that what they wear underneath the FR clothing directly affects how it will perform. They should know what would happen if they wear cotton or synthetic clothing under the FR garments.

- Your work environment is vastly different from the lab environment. For example, you may purchase an FR cloth with a 180°C rating. While the temperatures at your workplace may be slightly less than this on average, they may not be constant. The temperature might rise higher occasionally, so the coverall won’t be adequate.

- Similarly, the workplace is not a controlled environment like a lab, so it may present different hazards which affect the risk level. You need to provide extra protective clothing to mitigate all the risks.

To finalize, safety managers must assess their needs to determine which protective clothing fits their circumstances. The protective garment will undergo all these test items, such as convective, molten, or heat resistance, so it’s your duty as a safety manager to determine what type and level of heat protection your workers need.

For instance, you shouldn’t purchase a protective garment with level 3 radiant heat protection when workers need level 2 protection against molten splash.

FAQs: Most confusing points

ISO 15025 vs. EN 11612

One can easily confuse ISO 15025 and EN 11612. But technically, ISO 15025 is one of the test methods contained in the EN 11612 standards and determines the flame spread properties of the FR protective clothing.

This test method includes a series of surface and bottom edge ignition tests. Some suppliers and manufacturers may provide test reports that may only state a flame spread test.

However, this can’t be claimed to be certified in EN 11612. To confirm the certification, you should assess the garments to verify that they passed both flammability tests. It should have labels A1 and A2 for procedures A and B, respectively.

Is Heat Resistance at 180°C a mandatory test item?

Yes. It is crucial that all protective clothing meets the minimum heat resistance requirement of 180°C. During fire hazards, the temperature can rise and cause the fabric material to self-ignite.

Why is the physical performance test important?

The physical performance includes the overall dimensional stability, tensile, tear, and burst strength of the garment fabric. It is vital as it makes the garment resist shrinkage during washing. And the fabric is strong enough to ensure that the clothes will not be worn out over time. In the long run, this makes it more durable.

“Certified” and “Meet the requirements” claimed by the supplier. What’s the difference?

When a supplier states that the protective clothing is certified, the fabric was tested and met all the required testing items in the EN 11612 standards.

It also insinuates that they got the test certificate and report (with total testing items) from an accredited laboratory. However, saying “meets all the requirements” could mean the fabric passed other unrelated tests, such as:

- Manufacturers don’t test the fabric but rather claim it as per their experience. For instance, they may have tested the material with similar fiber blends or weights.

- The fabric passed the ISO 15025 flame spread tests without heat resistance tests, and they only have a test report for the flammability test.

Caution

The flame-resistant fabric for protective clothing must meet multiple standards. That is because most workplaces have more than one hazard (multiple hazards). For instance, in the oil & gas industry, the worker may meet risks of:

- Welding spark (EN 11611)

- Electronic-static (EN 1149-3/5)

- Low visibility (EN 20471)

- Electric arc (IEC 61482-2)

- Chemical splash (EN 13034)

- Rain hazards (EN 343).

We shall cover these standards later in our blog.

Conclusion

To sum up, it is also essential to take note of the following insights.

1: Besides the FR properties, buyers should also pay attention to the physical performance of the fabric. For example, if the FR fabric shrinks, it will tear a hole, and pieces will fall out, causing it to have limited protection.

2: All tests are simulations, which do not reflect the complete picture of the real world. In a working environment, the situation can be even more complex. Multi-risk protection is necessary.

3: Pay more attention to the testing claims by a manufacturer. Ensure the protective clothing conforms to all the standards mentioned in their report.

4: As a safety manager, you should remember that fire-resistant clothing can be certified even after meeting the standards of only one of the five heat resistance tests. It would be best if you thus verified that it is suitable for its intended purpose. For instance, if you buy an FR suit for a firefighter, ensure it goes through the contact heat resistance test.

2 thoughts on “Understanding EN 11612 standard: Heat & Flame Protective Clothing & Textile”

Hi Kevin

I work in purchasing at a processing plant – we process metals such as zinc and lead.

I am researching suitable FR fabrics for our plant users. We require a coverall to protect from molten metals and also an arc rating (2) protection for our electrical workers

Hoping you can provide some options or further understanding if this wishlist is at all possible?

Look forward to hearing from you

Thank you

Kayla

Hi Kayla,

Thanks for your comment. I just send you an email to offer our assortment.

Regards,

Kevin