The flame-resistant protective clothing market is booming, thanks to a demand boost caused by the increasing need for occupational health & safety. But one name stands head and shoulders above the rest: modacrylic fabrics.

Modacrylic fabrics have become popular in recent years for their unique blend of properties that make them ideal for a variety of applications. Their combination of flame retardant and thermal insulation qualities, for instance, makes them a good choice for making protective clothing.

And their soft, comfortable texture has led to their growing popularity as a versatile fiber. What many people may not know, however, is that modacrylic also has some disadvantages. For example, it tends to shrink when exposed to high temperatures.

In this article, we’ll walk you through the features of modacrylic fabrics and explore what sets modacrylic fabrics apart from the other FR fabrics. Before we dive into this topic, let’s get to know the modacrylic fiber.

What is Modacrylic?

While traditional FR clothing is often too heavy or too hot for the job, modacrylic fabrics are the polar opposite. Modacrylic is a synthetic fiber similar to acrylic, made up of 35-85% by weight of acrylonitrile units.

Properties

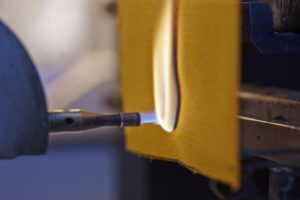

As the flame retardant chemicals built into the polymers that make up modacrylic fibers, modacrylic has inherent flame-retardant properties. That makes modacrylic fabric a robust answer against flash-fires and electric arcs as it will not melt or burn if exposed to high temperatures.

What’s more, modacrylic is lightweight, breathable, durable, stain resistant, and flexible. Surprisingly, it is less expensive than acrylic but more durable —all the things you want in a protective fabric.

Applications

- Protective apparel: high-performance protective clothing to shield against severe burns.

- Wigs and hairpieces: modacrylic fiber has an almost wool-like feel, making it ideal for making wigs and faux fur.

- Industrial fabric: used in non-woven filters, automotive batteries, vehicle interior materials, and paint-roller covers.

- Upholstery and household items: woven into various things like toys, drapery, furlike rugs, duvets, mattresses, throws, and blankets

Manufacturers of Modacrylic Fiber

Many years have passed since modacrylic fiber was first invented in 1949. There are several manufacturers still active in the market today, the first two of which are the dominant players in the market.

Kaneka Corporation – Protex Modacrylic

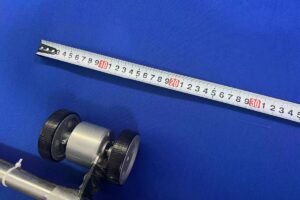

Kaneka Corporation in Japan manufactures Protex, a modacrylic fiber with a high luster and surface gloss. The company then derives Protex C with a 32 limiting oxygen index (LOI) and Protex M (LOI 34).

LOI refers to the minimum oxygen capacity of protective clothing to support combustion, so the higher the LOI number, the lower the chance of it combusting.

Kaneka utilizes Protex to make protective clothing, bedding, home textiles, and industrial and interior applications.

Fushun Rayva Fiber Co., Ltd (China) – Sevel Modacrylic

The company makes two types of modacrylic fiber: FRS and FRSA. FRS has an LOI of 28, while FRSA has an LOI of 32.

We, WOKI FR, are the leading distributor of Sevel Modacrylic fiber in China. If you are looking for a reliable source of modacrylic fiber, be sure to contact us today. We can provide you with all the information you need to make an informed decision.

Aksa Akrilik Kimya San. A.S (Turkey)

Aksa Akrilik Kimya San. A.S, Turkey is a manufacturer of modacrylic fiber, with an annual capacity of 308,000 tons. It produces various acrylic fibers and the ARMORA®, a high-quality, premium yarn made from 100% modacrylic fiber.

Armora modacrylic fiber is excellent for making upholstery, soft furnishings, protective garments, and industrial applications.

Formosa Chemicals & Fiber Corporation (Taiwan)

Formed in 1954, Formosa Chemicals & Fiber Corporation provided a domestic source of fiber and chemicals. The company closed down its modacrylic fiber division but remained integral to its history.

Why You Should Consider Modacrylic for Your Protective Clothing Fabric

Modacrylic fiber has some key benefits that make it ideal for protective clothing fabric. Here are five features you should know about.

1. No Secondary Injuries

One of the critical benefits of modacrylic fiber is that it doesn’t melt or drip when it catches fire. It means you won’t get secondary injuries from melted acrylic as you would from other fabrics, even when patting a fire out from your clothing.

2. Long Last FR Properties

Users love modacrylic because it has inherent FR protection. You won’t need to treat the fabric to chemically enhance its fire retardant properties.

Moreover, you can wash it regularly without fading its flame retardant properties or causing wrinkles.

3. Compatible with other fibers

Modacrylic fiber is so versatile that it blends with several different types of fibers. The goal of the blend is to increase the heat & flame protection or wearing performance of the fabrics. Combining different types of fibers produces a textile with improved properties over those made by just one fiber.

- Cotton: this is the most common blend found in FR protective garments. The fabrics do not lose their FR properties after the combination with non-FR fibers.

- Viscose (Tencel, Lyocell): above 20% ratio used in the blend will improve comfort and breathability through wicking and moisture management. A viscose and modacrylic blend makes the fabric more comfortable, absorbent, and breathable.

- Nylon: As nylon is a high-strength, abrasion-resistant fiber, it can improve strength and durability while reducing the pilling of the blend fabric.

- Aramid: interweaving modacrylic and aramid fibers is an excellent way of improving their thermal protective performance (TPP value). The process increases the resultant fabric’s arc thermal protection value (ATPV), making it the best lightweight protection against arc.

- Polyester: when blended with polyester, it gives the textiles a higher dyeing rate. That makes it suitable for HiVis clothing in yellow or orange as required by EN 20471 standard.

4. Alternative for Cost-Effective Inherent FR Fabric

Modacrylic is a cheaper alternative to the equally impressive Nomex and Kevlar used in making protective garments, gloves, and blankets.

5. It Offers True Comfort

Modacrylic is a synthetic fiber that offers warmth, softness, and comfort, which makes it a no-brainer for everyday protective clothing.

Although it’s a lightweight material, it does excellent as winter wear. The material traps warm air in the fibers.

On the other hand, the fabric also wicks moisture away from the body, which helps keep your skin dry in cool temperatures.

Do you have sensitive skin issues? No problem! Since modacrylic is non-allergenic, it’s an ideal choice for those who wear FR baselayer next to the skin.

Modacrylic is the answer for anyone concerned about the comfort of protective clothing.

5. Multi-Hazard Protection in One Fabric

As above, modacrylic blends with other high-performance fibers to obtain multi-hazard protection in one fabric:

- Abrasion resistance

- Limited Molten metal splash

- Chemical resistance

- High visibility

- Anti-static

- Electrical arc resistance

Modacrylic vs. FR Polyester

Modacrylic is a modified acrylic fiber with inherent flame retardant capabilities. It has a high resistance to chemicals like solvents and acids.

On the other hand, FR polyester is a polyester fiber with flame retardant properties. To come up with FR polyester, you typically run it through conversion coating. It’s a process where the polyester fiber gets mixed with a resin that makes it resistant to fire.

While FR polyester has an LOI value above 26, modacrylic’s LOI is between 28 and 33. When FR polyester burns, it will melt, and those pieces could burn your skin. That doesn’t happen with modacrylic fiber.

Polyester products release chemicals, such as phthalates, into the air and some are absorbed into your skin, causing hormone disruption. They are non-absorbent, so they will leave you hot and sticky. Since it is a synthetic product, polyester will cause skin irritation to people with sensitive skin.

You won’t experience any of that with modacrylic fabric, so that makes it the perfect choice for baselayer clothing as it is skin safe, lightweight, absorbent, and won’t combust easily.

Conclusion

Modacrylic is increasingly becoming the de facto FR fabric for protective clothing and with good reason. Apart from its inherent flame retardant properties, it does not melt or drip during fire exposure and offers superior chemical resistance.

You can also combine it with other fibers to improve their protection. That’s not even mentioning that it is a versatile, lightweight material that’s non-allergenic.

And did we mention it’s cost-effective? You can also add long-lasting FR properties that do not fade with washing to its list of accomplishments.

You can dye modacrylic easily and use it to make various clothing items such as sweatshirts, and hoodies, which means it has changed the style of daily work wear, making them more fashionable and not as dull and old-fashioned as before.

Today’s protective clothing market is increasingly taking into account the comfort of the wearer without compromising the protection performance.